Welding instruments with position change function

Welding instruments with the position change function are specialized devices equipped with mechanisms that allow modification of the position of the device along with the structure being processed. This solution allows free access during complex assembly and welding operations. They are used for tacking, welding of metal frame, box and skeleton structures of larger and smaller dimensions, requiring precise positioning of their components. They are used as part of processing lines, most often in the production of rail and wheeled vehicles – rail cars, locomotives, buses and cars.

HAK Sp. z o.o. has many years of experience in the comprehensive production of welding instruments with the function of changing positions, ranging from their design, through production, assembly, to commissioning and on-site testing. We manufacture equipment for entire processing lines, and the quality of our equipment is confirmed by a quality control certificate and CE mark.

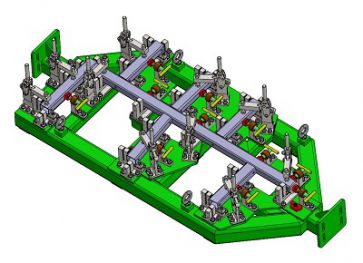

Device with rotators for welding small steel structures with the possibility of turning together with the workpiece.

Devices with two-column rotators for welding medium-size frame structures - with the option of rotation and changing the level of workpiece.

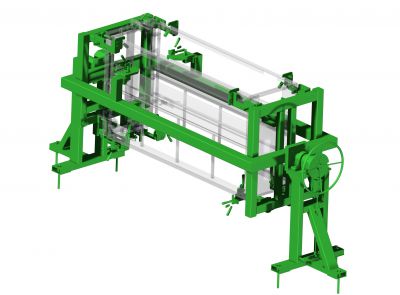

Rotary assembly and welding jig for welding of long-type steel structures - equiped with electric rotator and manual clamps.

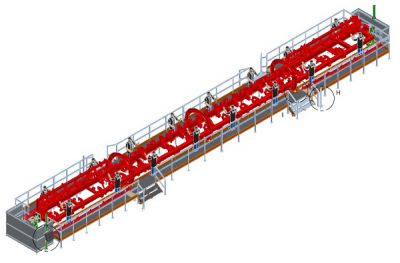

Device with rotators for welding long box steel structures, it enables workpiece rotation.

A device with rotators for welding long spatial steel structures, it enables workpiece rotation.

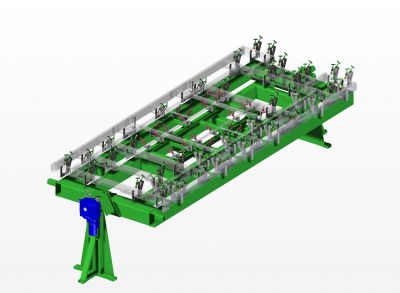

Device with two-column rotators for welding long spatial frame structures with the option of rotation and changing the level of the components.

Devices with two-column rotators for welding long spatial frame structures with the option of rotation and changing the level of the components.

Devices with an electric rorator for welding small, compact spatial steel structures with the possibility of rotating workpieces.